Byron F15c Project

#78

My Feedback: (2)

I'm not an expert by any stretch when it comes to pipes and pipe efficiency but I see what I would think are a couple of concerns. First off, that is not a bell mouth. That's a funnel that looks to me like it should be attached to a full bypass. The shape of a bellmouth and the gap that should be between the turbine and the front of the bellmouth are what allows air to be pulled into the pipe and help cool things down. I would expect to see overly high temperatures with the set up you have. The only other thing that I'm not sure of and maybe it's not important, but every bifurcated pipe I have seen has a straight section leading from the bellmouth to where the pipe Y's. That may or may not be an issue, I've just never seen one that is just a V shape with no straight pipe section. That funnel you have may or may not work, but here is what every bifurcated pipe I've ever seen has looked like and what a proper bellmouth looks like. If you were running full ducting from inlets to a bypass direct to the pipe I'd have no concerns with that funnel and as I say it might be fine I really don't know, but I'd be extremely cautious of your temps when doing first runs.

RP

#79

Well, got a little more done, on the turbine mount, I'm not really worried about the bifurcated pipe, I do have a temp gun, after building and flying 42% planes, I think everything is going to be ok, but I do appreciate everybody comments and inputs, you can learn a little, from everybody.

#80

My Feedback: (22)

It's not so much the pipe temp or fuse I'm concerned about, that will be easy to tell if it's too hot. If you cant hold your hand on the outside of the fuse for more than a second or two it's too hot.

I'm more concerned about the egt of the engine itself. Improper spacing between the engine and pipe or improper design of the pipe can lead to the turbine running too hot. In a good case scenario the engine just over temps and shuts down. In a worst case it kills the bearings and causes internal damage.

the purpose of a bellmouth inlet is to allow a smooth draw of outside air from around the pipe to the inside of the pipe with a venturi effect. This helps keep the egt of the turbine down.

#82

My Feedback: (3)

My project is virtually identical to yours. I have an old Byron F15C that has never been flown. I have a lot of questions. Right now, I'm a bit confused as to the configuration of the main wing spar, or spars. Mine has one little spar near the rear of the main wings...and that's it. Can you show some pictures of your main wing spars, how long they are, and how they mount inside the fuselage?

Also, I'm going off the Fly Eagle Jets F15 that friend of mine has. His hatch is on top, but much farther forward than yours. In fact, the air brake is part of the main engine hatch. He used the Feibo twin pipe with a single engine, and I have that same pipe. Just wondering why you thought the Feibo pipe was too long? Did someone already cut that rear hatch before you got the plane?

Also, I'm going off the Fly Eagle Jets F15 that friend of mine has. His hatch is on top, but much farther forward than yours. In fact, the air brake is part of the main engine hatch. He used the Feibo twin pipe with a single engine, and I have that same pipe. Just wondering why you thought the Feibo pipe was too long? Did someone already cut that rear hatch before you got the plane?

#83

Well, a congrats is in order, yes there is a aluminum spar, it's about 4" long, I've then the as 6" long on some Byron f15, I chose to put my turbine at the rear, there's a guy name Sherlock, he had a Byron F15c, that was built by a guy name Kim, he is very skilled turbine jet builder, and he chose to put the turbine near the rear and it was one the best flying f15 I've seen, and putting the 100oz fuel tank between the retract is perfect with the CG, so I'm copying Kim build. x

x

c

x

x

c

#89

Hey guys

You have to keep in mind that these planes were designed to fly with twin DF, that when running good were pulling between 20 to 25 lbs. In my opinion running more than a 120 turbine is asking for trouble if no reinforcement is done to the plane, and not only to the wings. If you expect it to fly like a modern kit especially designed for turbines without a lot of reinforcment, it probably wonīt last long.

I have a converted Avonds F-15 that I flew for ten years with a single OS 91 Ramtec fan. Now its flying with a KT 100 turbine, I didnīt reinforce the wings or stabs, only put some carbon fiber in the fuse in some key parts and changed the retracts. It flys great, I only use full power for take off and then I fly arround at max 80% power and it is a lot of fun.

Regards

Eduardo

You have to keep in mind that these planes were designed to fly with twin DF, that when running good were pulling between 20 to 25 lbs. In my opinion running more than a 120 turbine is asking for trouble if no reinforcement is done to the plane, and not only to the wings. If you expect it to fly like a modern kit especially designed for turbines without a lot of reinforcment, it probably wonīt last long.

I have a converted Avonds F-15 that I flew for ten years with a single OS 91 Ramtec fan. Now its flying with a KT 100 turbine, I didnīt reinforce the wings or stabs, only put some carbon fiber in the fuse in some key parts and changed the retracts. It flys great, I only use full power for take off and then I fly arround at max 80% power and it is a lot of fun.

Regards

Eduardo

#90

My Feedback: (3)

Hey guys

You have to keep in mind that these planes were designed to fly with twin DF, that when running good were pulling between 20 to 25 lbs. In my opinion running more than a 120 turbine is asking for trouble if no reinforcement is done to the plane, and not only to the wings. If you expect it to fly like a modern kit especially designed for turbines without a lot of reinforcment, it probably wonīt last long.

I have a converted Avonds F-15 that I flew for ten years with a single OS 91 Ramtec fan. Now its flying with a KT 100 turbine, I didnīt reinforce the wings or stabs, only put some carbon fiber in the fuse in some key parts and changed the retracts. It flys great, I only use full power for take off and then I fly arround at max 80% power and it is a lot of fun.

Regards

Eduardo

You have to keep in mind that these planes were designed to fly with twin DF, that when running good were pulling between 20 to 25 lbs. In my opinion running more than a 120 turbine is asking for trouble if no reinforcement is done to the plane, and not only to the wings. If you expect it to fly like a modern kit especially designed for turbines without a lot of reinforcment, it probably wonīt last long.

I have a converted Avonds F-15 that I flew for ten years with a single OS 91 Ramtec fan. Now its flying with a KT 100 turbine, I didnīt reinforce the wings or stabs, only put some carbon fiber in the fuse in some key parts and changed the retracts. It flys great, I only use full power for take off and then I fly arround at max 80% power and it is a lot of fun.

Regards

Eduardo

#91

Eduardo, the plan IS to do a lot of reinforcement. The elevator system needs to be upgraged to needle bearings, it needs a 2nd spar, the fuse needs carbon reinforcement, the plastic struts and gear flange needs to be replaced, the aileron bellcranks are nylon and need metal instead, the servo bays are too weak, it needs more formers...and on and on.

#93

My Feedback: (22)

Don't get me wrong, the Byron F15 was a monster and a really nice airplane, really an iconic airplane for the time, but nowhere near 200mph. With the added weight of fuel and the reinforcing you are doing I would strongly consider a second spar, just my opinion but even the jet legend F15 which is quite a bit smaller has 2 spars. Just my 2 cents.

#94

My Feedback: (3)

205mph? Hardly. 105mph would be believable, maybe even 150 but the byron bullet was the fastest jet byron ever made and it was nowhere near 200mph. Even the BVM stuff was a challenge to break 200mph with. They would do it but they were 1000x more efficient than the byron stuff.

Don't get me wrong, the Byron F15 was a monster and a really nice airplane, really an iconic airplane for the time, but nowhere near 200mph. With the added weight of fuel and the reinforcing you are doing I would strongly consider a second spar, just my opinion but even the jet legend F15 which is quite a bit smaller has 2 spars. Just my 2 cents.

Don't get me wrong, the Byron F15 was a monster and a really nice airplane, really an iconic airplane for the time, but nowhere near 200mph. With the added weight of fuel and the reinforcing you are doing I would strongly consider a second spar, just my opinion but even the jet legend F15 which is quite a bit smaller has 2 spars. Just my 2 cents.

#98

My Feedback: (3)

A lot of people exaggerate. I'm skeptical of 205mph with a twin ducted fan getting the kind of air velocity needed without the direct fuel-air expansion that happens inside a turbine. But then who ever thought gliders would go over 400mph? In the end, it doesn't matter. I'll be adding a 2nd spar and a lot more carbon reinforcements. One are of special interest is I think the full flying stab pivoting system needs an upgrade with bearings and a thicker pivot shaft. I don't think that thin brass sleeve is going to be adequate.

#100

My Feedback: (22)

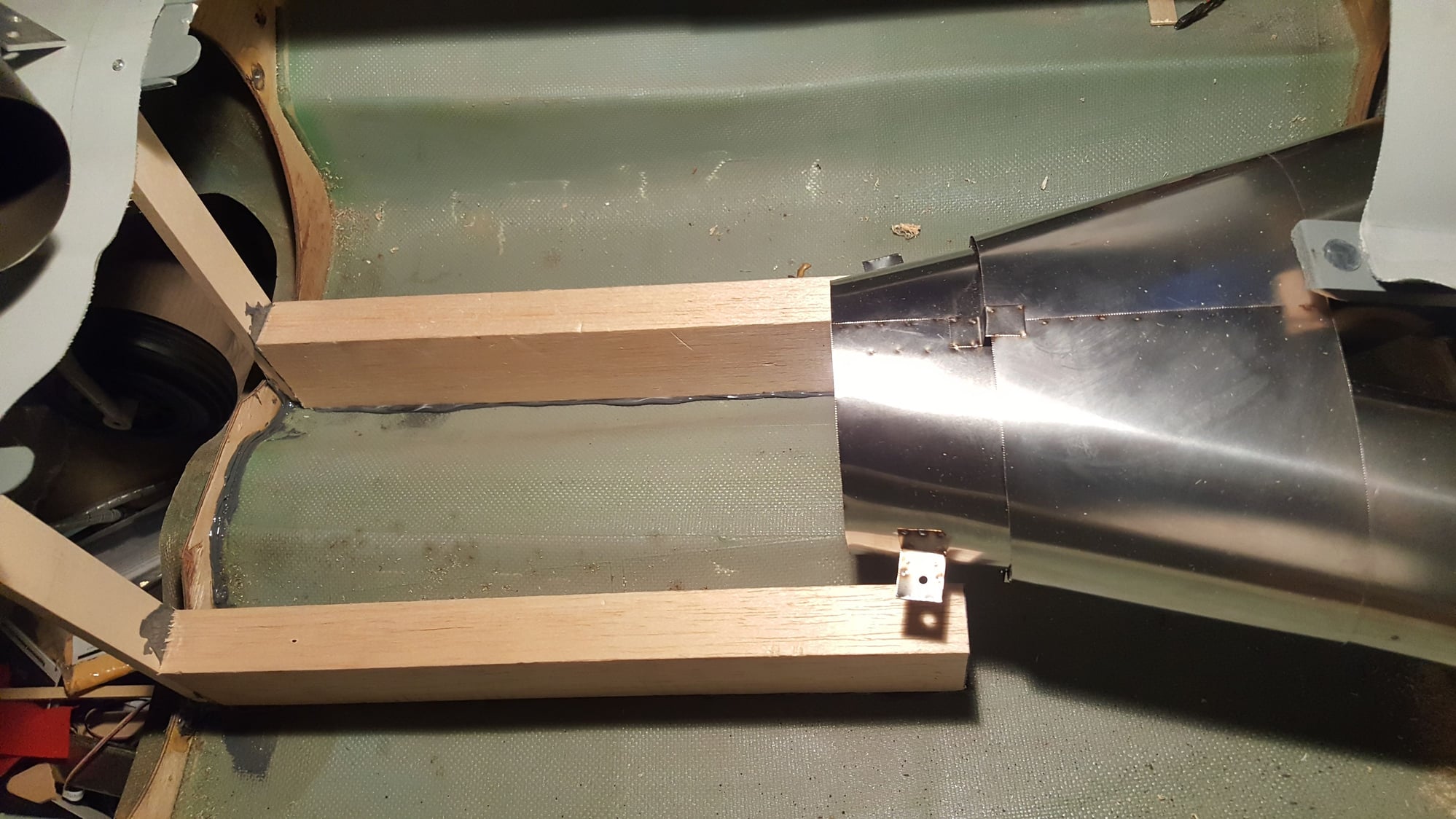

Agreed. I have a couple of concerns with the turbine mount, take them as you wish.

first of all, its overbuilt with IMO inadequate materials. What I mean is, you have a lot of pieces there that are not necessary but balsa is not a material I would have ever used as a structural piece. Nor would I have used the aluminum, it is an overkill material but tied I to an inadequate material.

I would have used the bulkhead that is there and added a 2nd bulkhead closer to the pipe that extended from wing root to wing root across the fuselage. Between the front and rear bulkhead simple 1/4" plywood engine mounting rails would have been more than sufficien . There is really no need for the excess epoxy and carbon fiber tow.

The other potentially significant issue I see is the entire mount is only tied into the one bulkhead and glued to the fiberglass fuselage skin. I can see a potential for a lot of flex where that structure is. This puts all of the shock load on that forward bulkhead on landings and all of the G load in flight on that bulkhead. The fiberglass skin really should not be viewed as a structural element. It is only strong when tied into bulkheads correctly. If it was only supporting the front of the pipe then it might be ok but the weight of the engine is another story.

Again, just my opinion but I've been flying turbines for 20 years this year and ducted fans prior to that. Pattern prior to that and making sure to support heavy objects in a fiberglass shell is extremely important.

first of all, its overbuilt with IMO inadequate materials. What I mean is, you have a lot of pieces there that are not necessary but balsa is not a material I would have ever used as a structural piece. Nor would I have used the aluminum, it is an overkill material but tied I to an inadequate material.

I would have used the bulkhead that is there and added a 2nd bulkhead closer to the pipe that extended from wing root to wing root across the fuselage. Between the front and rear bulkhead simple 1/4" plywood engine mounting rails would have been more than sufficien . There is really no need for the excess epoxy and carbon fiber tow.

The other potentially significant issue I see is the entire mount is only tied into the one bulkhead and glued to the fiberglass fuselage skin. I can see a potential for a lot of flex where that structure is. This puts all of the shock load on that forward bulkhead on landings and all of the G load in flight on that bulkhead. The fiberglass skin really should not be viewed as a structural element. It is only strong when tied into bulkheads correctly. If it was only supporting the front of the pipe then it might be ok but the weight of the engine is another story.

Again, just my opinion but I've been flying turbines for 20 years this year and ducted fans prior to that. Pattern prior to that and making sure to support heavy objects in a fiberglass shell is extremely important.